Best DEKTON® Diamond Blades

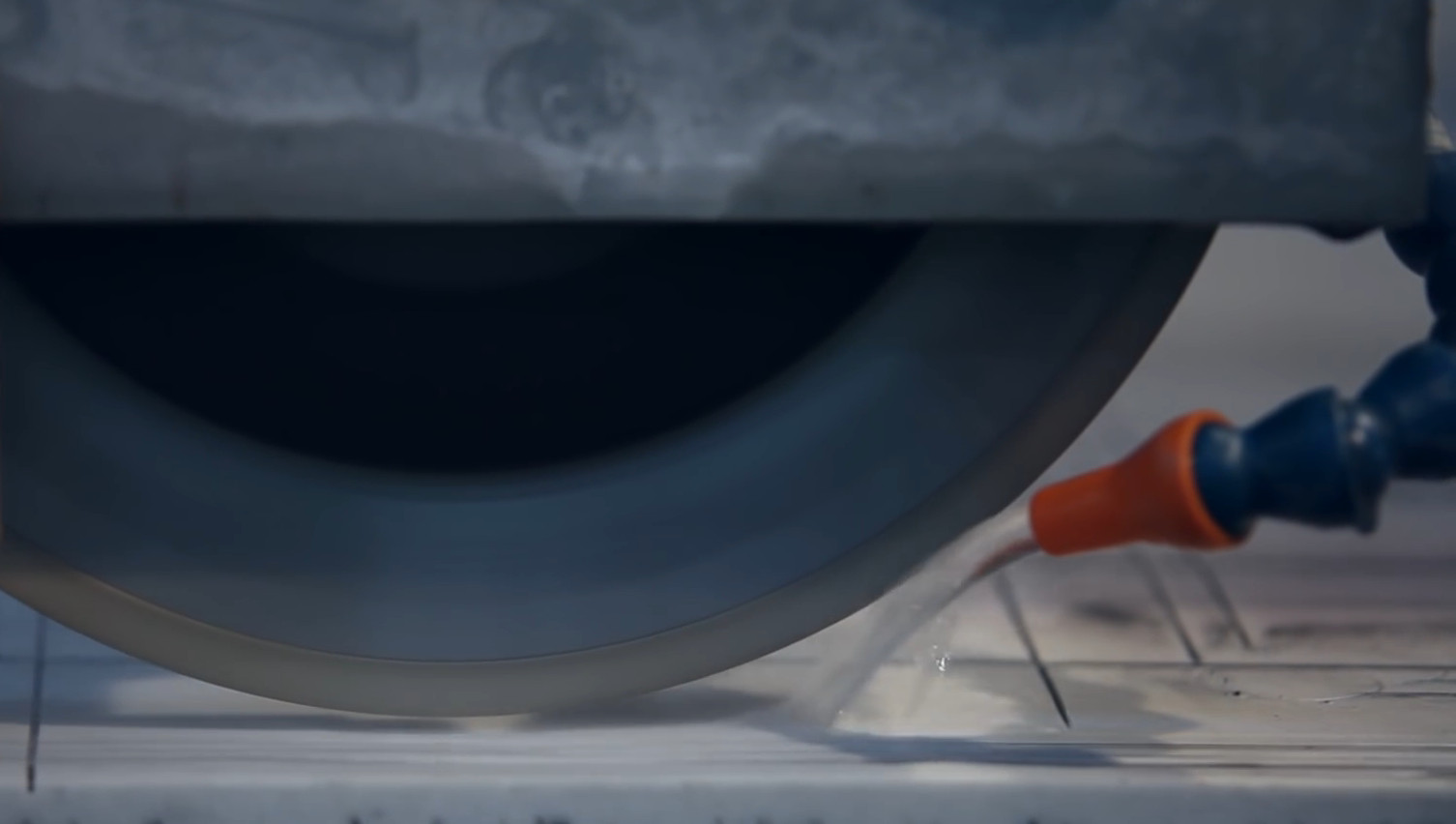

When it comes to cutting ultracompact surfaces, fabricators seek diamond tooling that designed specifically for cutting these types of surfaces. Even very dense materials like porcelain and ceramic can require special cutting equipment. It stand to reason then that DEKTON® would need a very tailored tool set. In this post, we are going to analyze some of the features of DEKTON® surfaces and consider some blades that have been specifically designed for use on this material that seems to be taking the stone industry by storm.

Continue reading “Diamond Blades for Dekton”