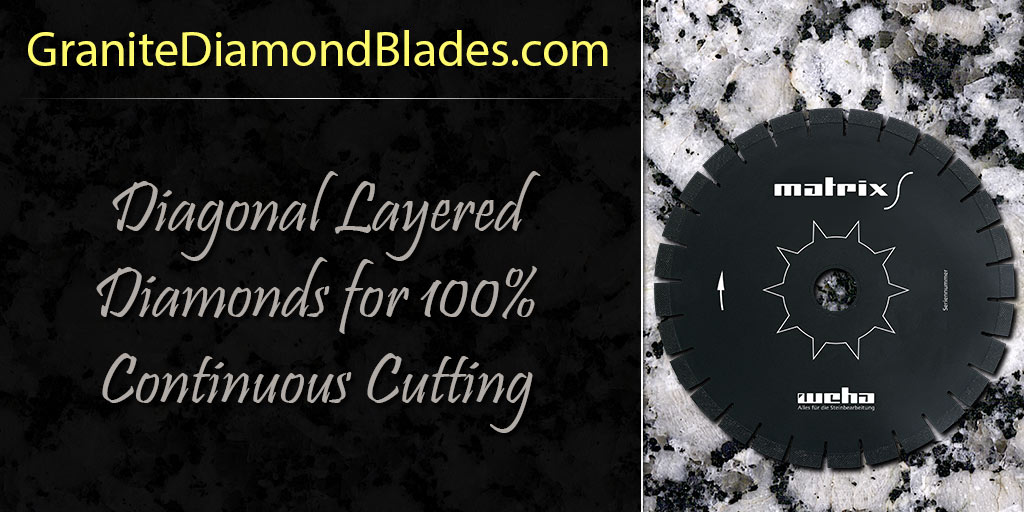

Split Segment Quartzite Blade – Grey Leopard

If you are looking for a bridge saw that cuts hard stone like quartzite fast and clean, you have found the right place. Let’s tak a brief look at why the Grey Leopard split segment quartzite blade is the choice of many fabricators that work with quartzite.

Continue reading “Grey Leopard”